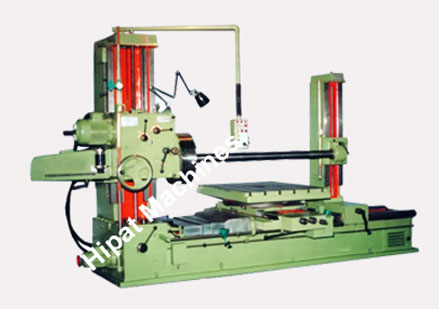

Horizontal Boring Machine

Standard Equipments

Electric Motors Complete with Panel Board & Pendant Control for all operations. One Steel Telescopic Cover, One Boring Bar, Working Spindle Support Guide for Vibration Control, Co-ordinate reading arrangement with Scales & Verniers for X. Y.Z.-Axis and Handles. Facing head, 2No. Lubricating Pumps, 5 No. limit Switches & Automatic Rapid Travel, fitted with the Machine. Revolving Centre with 6″True Chuck Three Nos. Dial Indicators duly fitted in dust proof housings with attachment & Electric Coolant Pump.

Extra Equipments

Milling Attachment.

Taper Boring Attachment.

Threading Attachment.

2Axis D.R.O.

PRICE: ON REQUEST

Order by Phone

0671-2505250

Shipping Information Usually dispatched With In business days.

Technical Specifications

| Model | AMI-1 | AMI-2 | AMI-3 | AMI-4 | AMI-5 |

|---|---|---|---|---|---|

| Alloy Steel Work Spindle Hardened & Ground-Diameter | 65 | 80 | 100 | 110 | 125 |

| MorseTaper Number | 4 | 5 | 6 | 6 | 6 |

| Max. Longitudinal Movements of Working Spindle | 410 | 510 | 510 | 510 | 600 |

| Number of Spindle Speeds | 9 | 9 | 9 | 9 | 9 |

| Range of Spindle Speeds – R.P.M. | 20 to 300 | 15 to 300 | 15 to 300 | 15 to 250 | 15 to 250 |

| Longitudinal Work Spindle Feeds Nos. | 9 | 9 | 9 | 9 | 9 |

| Max. Height of the Spindle Axis from Table Surface | 800 | 925 | 1000 | 1100 | 1200 |

| Min. Height of the Spindle Axis from Table Surface | 20 | 25 | 30 | 30 | 30 |

| Dimensions of the Rotary Table | 840 x 1050 | 900 x 1105 | 1030 x 1375 | 1100 x 1450 | 1220 x 1675 |

| Longitudinal Table Traverse | 1500 | 1625 | 1775 | 1925 | 2050 |

| Long. Table Traverse Feeds (Including one Rapid) | 10 | 10 | 10 | 10 | 10 |

| Transversal Table Travel Feeds (Including one Rapid) | 10 | 10 | 10 | 10 | 10 |

| Vertical Head Stock Travel Feeds Includin one Rapid | 4 | 4 | 4 | 4 | 10 |

| Rotary Table Automatic Feeds (Including one Rapid) | Nil | 10 | 10 | 10 | 10 |

| Max. Cross Movement of the Table | 910 | 1000 | 1100 | 1 300 | 1500 |

| Max. Distance between Stay Bearing & Facing Head | 2150 | 2400 | 2690 | 2800 | 2950 |

| Facing Head Diameter | 450 | 505 | 555 | 600 | 650 |

| Weight Approximate in Kgs. (with Packing & Accessories) | 7500 | 9500 | 11500 | 14500 | 18000 |

| Weight Approximate in Kgs. (without Packings Accessories) | 7000 | 8500 | 9500 | 11000 | 13500 |

| Power Motor (HP) | 3 & 1.5 | 5 & 2 | 7.5 & 2 | 10 & 3 | 12.5 & 5 |

| OPTIONAL ACCESSORIES | STANDARD ACCESSORIES | APPLICATIONS |

|---|---|---|

| 1. Facing Head | 1. Electric Motors | 1. This machine is best suited for small batch production or when cost of press tools and dies is prohibitive. |

| 2. Milling Attachment | 2. Pannel Board | 2. Die & Mould Manufacturers |

| 3. Taper Boring Attachment | 3. Coolant Pump | 3. Aerospace |

| 4. Threading Attachment | 4. Medical Equipment | |

| 5. Micro Boring Head | 5. Textile Machinery | |

| 6. Digital Read Out | 6. Diamond & Jewellery Industries | |

| 7. Allied Machinery | ||

| 8. Plastic Processing Machinery | ||

| 9. Defence |