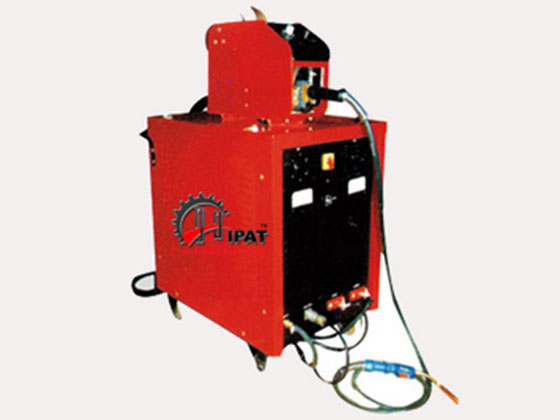

Mig/Mag Welding Machine

It is multi-system welding unit having the three most common welding methods in the same package. It is based on the most up-to-date technology in the welding field. Many divfferent auxillary functions simplyfy the work of the welder and increase the productivity of his work. It is most suitable where a job demands a continuous change of welding method. The following different facilities are provided in one package

MANUAL METAL ARC WELDING ( MMA )

TIG WELDING

MIG/MAG WEDLDING

PRICE: ON REQUEST

Order by Phone

0671-2505250

Shipping Information Usually dispatched With In business days.

Surface Grinding Machine

| POWER SOURCE | MODEL | 262 | 462 |

|---|---|---|---|

| Static Characteristics | |||

| Input Supply Voltage Phase Frequency |

V Nos. HZ |

415 3 50 |

415 3 50 |

| Rating 100% Duty Cycle | KVA | 12 | 25 |

| Max. Input Current at Rated Output With 415VSupply |

AMPS | 14 | 28 |

| Open Circuit Voltage Maximum Welding Current |

V AMPS |

16-42 250 |

18-54 400 |

| Maximum Welding Current/ Load @100% Duty Cycle |

Amps/ Volts |

250 | 400 |

| Type of Cooling | Forced Air Cooling | ||

| Class of Insulation | Class F | Class F | |

| WIRE FEEDER | MODEL 262 | 462 |

|---|---|---|

| Wire Diameter Mild Steel mm Stainless Steel mm Aluminium mm |

0.8-1.2 0.8-1.2 1.2-1.6 |

0.8-1.2 1.2 1.6 |

| Wire Drive Motor Type | PermanentMagnet DC Motor | |

| Drive System Type | 2 – Roll Quick Release | |

| Wire Feed Speed M/Min | 0 to 20 | 0 to 20 |

| WIRE FEEDER | MODEL | FEEDINV-500 |

|---|---|---|

| Wire Diameter | ||

| Wire Drive Motor | Type | Permanent Magnet DC MOTOR |

| Drive System | Type | 2 – Roll Quick Realease |

| Wire Feed Speed | m/min | 0 to 20 |

| TORCH(Binzel make) | MODEL | MTG-250 | MTG-400 |

|---|---|---|---|

| Rated Current at 100% Duty Cycle Co2 |

AMPS | 250 | 400 |

| Cable House Length | Mtr. | 3 | 3 |

| Cooling | Type | Gas | Gas/Water |

| POWER SOURCE | L | W | H |

|---|---|---|---|

| MIG/MAG462 | 720mm | 460mm | 610 mm |

| MIG/MAG262 | 560mm | 460mm | 670 mm |

| WIRE FEEDER | 720mm | 460mm | 610 mm |

| OPTIONAL ACCESSORIES | STANDARD ACCESSORIES | APPLICATIONS |

|---|---|---|

| 1. Co2 Regulator cum Flow Meter | ||

| 2. Helmet With Glass | ||

| 3. Pair of Hand Gloves | ||

| 4. Wire Brush | ||

| 5. Apron and Spray |