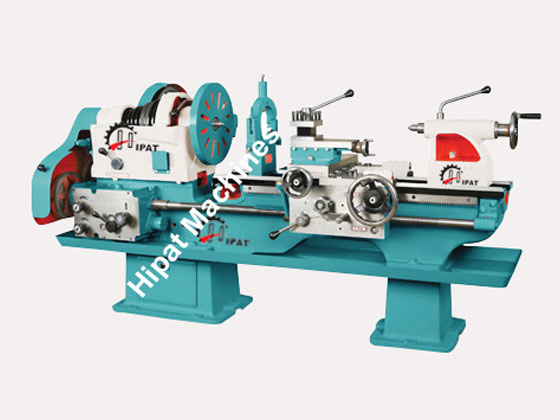

High Precision Lathe Machine

A toolroom lathe is a lathe optimized for toolroom work. It is essentially just a top-of-the-line center lathe, with all of the best optional features that may be omitted from less expensive models, such as a collet closer, taper attachment, and others. There has also been an implication over the years of selective assembly and extra fitting, with every care taken in the building of a toolroom model to make it the smoothest-running, most-accurate version of the machine that can be built. However, within one brand, the quality difference between a regular model and its corresponding toolroom model depends on the builder and in some cases has been partly marketing psychology. For name-brand machine tool builders who made only high-quality tools, there wasn’t necessarily any lack of quality in the base-model product for the “luxury model” to improve upon. In other cases, especially when comparing different brands, the quality differential between (1) an entry-level center lathe built to compete on price, and (2) a toolroom lathe meant to compete only on quality and not on price, can be objectively demonstrated by measuring TIR, vibration, etc. In any case, because of their fully ticked-off option list and (real or implied) higher quality, toolroom lathes are more expensive than entry-level center lathes.

PRICE: ON REQUEST

Order by Phone

0671-2505250

Shipping Information Usually dispatched With In business days.

Technical Specifications

| MODEL | RANGE | A.B.C | WEIGHT (Approx) |

Floor L |

Space W |

Occupied | |

|---|---|---|---|---|---|---|---|

| HGT-5 | 5.5 FEET | 1675 MM | 550 MM | 1100 KG | 1980 (78″) | 1250 (49″) | 1370 (54″) |

| HGT-6 | 7 FEET | 2130 MM | 1000 MM | 1300 KG | 2425 (95″) | 1250 (49″) | 1370 (54″) |

| HGT-9 | 9 FEET | 2740 MM | 1560 MM | 1500 KG | 3050 (120″) | 1250 (49″) | 1370 (54″) |

| HGT-10 | 10 FEET | 3048 MM | 1860 MM | 1700 KG | 3350 (132″) | 1250 (49″) | 1370 (54″) |

| HGT-12 | 12 FEET | 3658 MM | 2450 MM | 1925 KG | 3950 (156″) | 1250 (49″) | 1370 (54″) |

| OPTIONAL ACCESSORIES | STANDARD ACCESSORIES | APPLICATIONS |

|---|---|---|

| 1. Electric Motor & Starter | 1. Face Plate(One) | 1. TOOL ROOMS |

| 2. Electric Coolant Pump | 2. Chuck Plate(one) | 2. TOOL & DIE MAKING |

| 3. 4jaw independent chuck | 3. Centers(Two center adapter(One) | 3. PRECISION MANUFACTURING |

| 4. 3jaw self centering chuck | 4. Stationery steady(One) | 4. EDUCATIONAL INSTITUTES |

| 5. Gears to cut metric threads | 5. Follow Rest Assembly(One) | |

| 6. Taper turning attachment | 6. Set of 22 change | |

| 7. Tool post grinder | 7. Gears (One) | |

| 8. Double Gap or Triple Gap etc. | 8. Motor Plate (One) | |

| 9. DIGITAL READ OUT (DRO) | 9. TOOL BOX | |

| 10. REVOLVING CENTRE | 10. INSTRUCTION MANUAL | |

| 11. NORTON GEAR BOX |